PSStech provides electrical services including panel/cabinet wiring and testing services for components and equipment that are used across the industry. We utilize only the highest performing equipment, with personnel who are skilled and trained, following all industry guidelines.

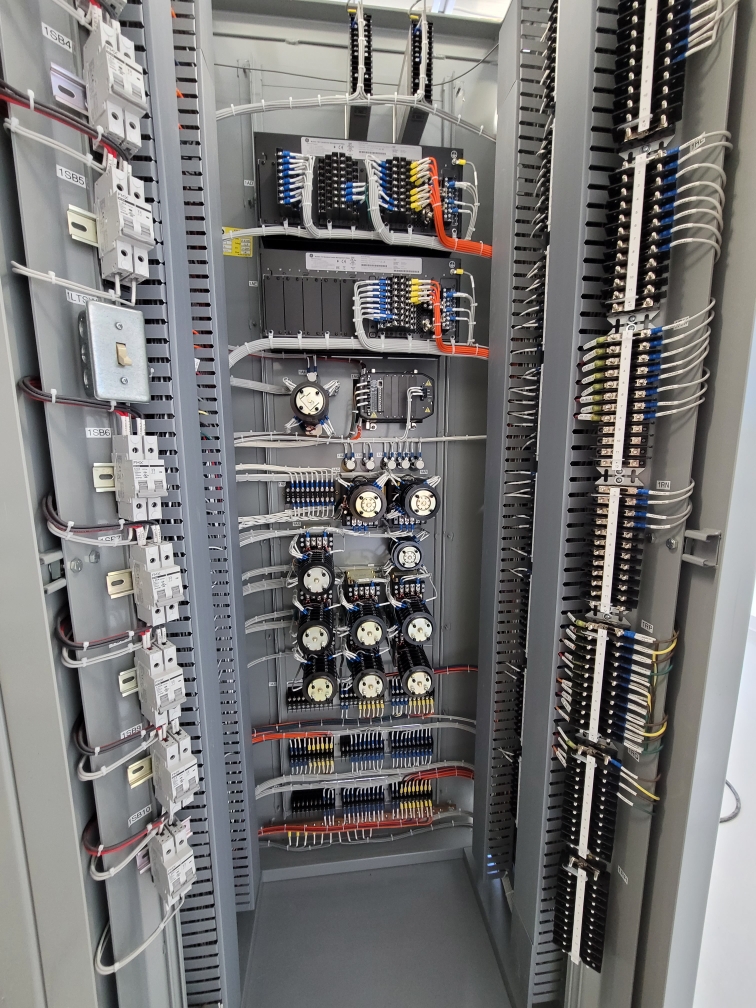

Control Cabinet/Panel Wiring

PSStech has extensive experience in development and integration of 19" rack systems, panels, and control cabinets. From single or multiple panel rack systems, through to full custom control cabinets, we deliver to your specifications. Our team uses your technical drawings and specifications to develop fully integrated rackmount solutions. A high level of accuracy means we capture every detail of your control cabinet configuration and hardware. Our services are ideal for multiple, identical cabinet installations.

Using our state-of-the-art machine and fabrication shop, we can customize control cabinet enclosures with safety glass, mesh, and steel ventilated doors. Customers can also select customized cable access and power management.

Whether you need controllers, switches, timers, encoders, machined and fabricated metalwork or even plastic products, we coordinate with your supply chain and deliver guaranteed traceability. From transportation through to industrial, telecoms, railways and renewable energy, we support diverse manufacturers with a range of integration capabilities including:

Electrical Testing, Trouble Shooting, and Failure Analysis

PSStech offers a full range of testing and troubleshooting services for components and equipment that are used throughout various industries. We utilize the highest performing test equipment, and our experienced personnel to ensure that our clients new or revamped electrical system will operate as it was designed, minimizing delays and costly electrical issues. We offer independent, third-party testing that provides reliability, integrity, and responsive services to meet all our client's power systems testing needs.

Having our experienced team test your electrical components and equipment can be very cost-effective and beneficial. This can help decrease unexpected downtime, reduce operating and maintenance costs, and get more capacity out of your existing assets.

The objectives of product testing are:

Our electrical testing and troubleshooting services include:

PSStech, LLC — 101 Skyline Drive, Warrior, Alabama 35180, USA

Phone: +1.205.631.3357

Email: info@psstech.com