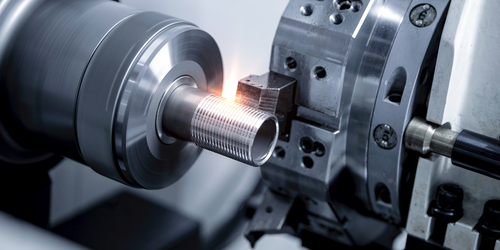

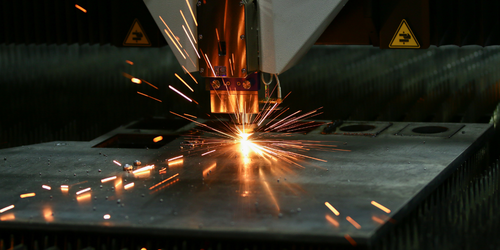

PSStech offers a wide range of precision machining solutions CNC milling, turning, and plasma cutting.

We speacilize in providing cost-effective OEM replacement solutions at a rapid rate.

Our Manufacturing/Prototyping process includes:

PSStech's Working Envelopes/Machinery Specifications

PSStech, LLC — 101 Skyline Drive, Warrior, Alabama 35180, USA

Phone: +1.205.631.3357

Email: info@psstech.com